Our tradition

Being technically ahead since the first original Schultze-RiRo in the 1950s.

Our success: The RiRo’s main features of being reliable, safe, robust and economical.

Our aim: Staying ahead, investing in our employees’ qualification and in new technology.

Our commitment: Keeping a lasting and trusting cooperation with our customers.

Constant work on new solutions, as our motivation is to find the technical edge.

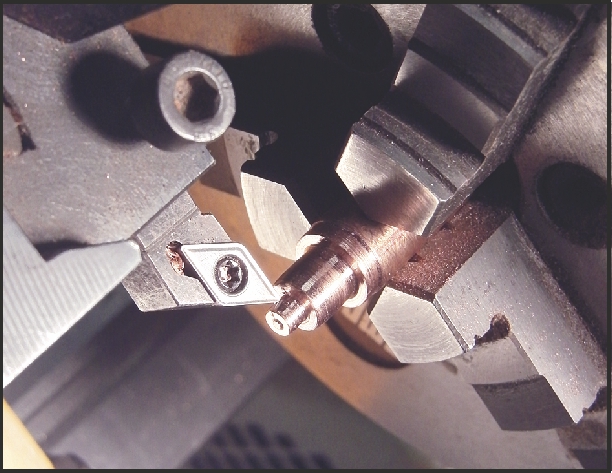

Precision and flexibility ensure optimal usefulness for our customers.

Final testing at high voltage of 1.750 V proves the RiRo’s safety.

Permanent manufacturing control, final testing and traceable stages of production guarantee maximum safety of every single RiRo.